Making best use of Efficiency: The Key Benefits of Timely Strapping Machine Repair Services

Prompt fixing solutions for strapping machines play a crucial function in optimizing efficiency within making procedures. Quick reaction times can greatly decrease tools downtime, bring about improved effectiveness. strapping machine repair. Normal maintenance not only prolongs equipment lifespan however likewise ensures regular product high quality. As companies intend to preserve an one-upmanship, recognizing the complex benefits of these services comes to be important. What certain benefits can companies acquire from prioritizing strapping maker repair work?

Decreasing Downtime and Its Influence on Operations

Reducing downtime is crucial for preserving functional effectiveness in any type of business that counts on strapping machines. When these machines experience breakdowns or break downs, assembly line can stop, bring about hold-ups and raised functional prices. Consequently, services may face challenges in meeting client needs, potentially damaging their track record and client partnerships. Timely fixing solutions can greatly reduce these issues by ensuring that makers are swiftly restored to come to a head functioning. Quick reaction times and effective troubleshooting are important, as they decrease the moment tools runs out service. Furthermore, a proactive approach to repair work can stop unexpected failures, enabling smoother production processes. By prioritizing timely strapping equipment repairs, organizations can maintain regular throughput, boost performance, and ultimately guard their bottom line. In this competitive landscape, minimizing downtime is not just advantageous; it is essential for sustained success.

Enhancing Equipment Life-span Via Regular Upkeep

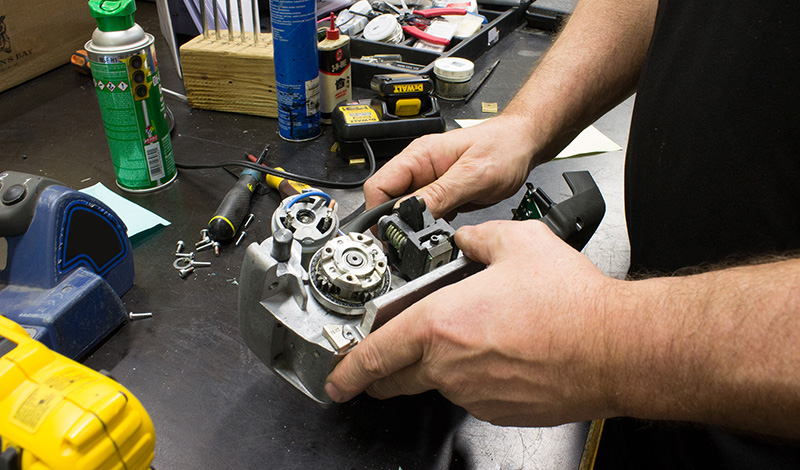

Routine maintenance plays a considerable duty in improving the lifespan of strapping devices, complementing the benefits of timely fixings. By sticking to a constant maintenance schedule, drivers can identify and deal with small issues before they rise right into major troubles. This positive method not just lessens the risk of unanticipated malfunctions however also assures that the makers operate at peak efficiency.

Regular jobs such as lubrication, belt modifications, and evaluation of vital components aid protect against deterioration, lengthening the tools's total life (strapping machine repair). Additionally, maintaining a clean workplace around the strapping devices decreases the likelihood of particles hindering efficiency

Buying regular upkeep not just extends the lifespan of the equipment however likewise adds to an extra reliable production process. Organizations that prioritize this method can expect boosted functional performance and reduced lasting expenses connected with devices substitute and comprehensive repair work.

Improving Item Top Quality and Uniformity

Guaranteeing item top quality and consistency is vital in product packaging operations. Enhanced packaging integrity and uniform strapping stress add greatly to reducing manufacturing irregularity. By resolving these variables, firms can accomplish higher reliability in their end products.

Enhanced Packaging Honesty

Enhanced packaging integrity is essential for preserving item high quality and consistency throughout the supply chain. When strapping devices operate at their best, they guarantee that products are securely packaged, reducing the danger of damages during transportation and storage space. Well-kept strapping devices supplies a trustworthy seal, avoiding contamination and spoilage, which is crucial for perishable items. In addition, boosted packaging stability fosters customer count on; customers are more probable to purchase items that get here in excellent problem. Timely repair services for strapping machines add appreciably to this integrity, minimizing downtime and guaranteeing consistent efficiency. By prioritizing machine maintenance, services can support their reputation for quality, eventually leading to greater client satisfaction and loyalty within an affordable market.

Attire Strapping Stress

Achieving uniform strapping stress is crucial for boosting item high quality and consistency throughout the product packaging procedure. When strapping makers run at perfect stress degrees, they assure that packages are firmly bound, minimizing the risk of damage during transit. Irregular tension can lead to excessively limited or loose bands, which might endanger the stability of the packaged products. Additionally, uniformity in strapping tension enables for standardized product packaging, boosting brand name discussion and consumer fulfillment. Timely repairs and upkeep of strapping devices aid maintain this essential uniformity, protecting against fluctuations that can impact total item quality. By focusing on uniform strapping tension, businesses can guarantee a reputable packaging solution that satisfies both functional standards and customer assumptions.

Decreased Production Irregularity

Uniform strapping tension directly contributes to lowering production irregularity, which is essential for maintaining high product top quality and consistency. When strapping devices run at peak performance, they ensure that items are safely fastened with consistent stress, decreasing the risk of defects such as loosened packages or product damages. This consistency not just improves the aesthetic charm of products however additionally boosts customer confidence in dependability. In addition, timely repair services and maintenance of strapping equipment protect against unforeseen malfunctions that can interrupt production routines, causing changes in result. By purchasing normal strapping maker repair services, makers can achieve a steady production setting, eventually resulting in improved general effectiveness and a greater rate of customer satisfaction through consistent product distribution.

Price Financial Savings From Preventative Fixes

Preventative repairs in strapping devices can bring about significant price financial savings for organizations. By resolving potential problems before they rise, business can properly decrease the danger of pricey malfunctions and production stops. Regular upkeep and timely repair services ensure that makers run at peak efficiency, minimizing energy usage and material waste. On top of that, preventative actions can extend the lifespan of devices, delaying the requirement for expensive substitutes.

Buying preventative repair services typically causes lower total fixing expenses compared to reactive upkeep, which can be expensive and unforeseeable. Services can additionally prevent the financial consequences of shed performance and delayed shipments created by unexpected equipment failures. By maintaining perfect efficiency levels, business can boost their affordable side. In general, focusing on preventative repair work for strapping equipments not only safeguards monetary sources but additionally cultivates a much more reliable manufacturing environment

Boosting Employee Morale and Productivity

Prompt repair services and maintenance not just shield economic sources yet additionally develop a much more positive workplace for staff members. When strapping devices are well-kept, the operations ends up being smoother, lowering stress and downtime. Staff members can concentrate on their tasks, understanding that the devices is efficient and dependable. This dependability promotes a complacency and confidence amongst employees, which can bring about enhanced work contentment.

Furthermore, when monitoring prioritizes tools maintenance, it indicates to employees that their well-being and performance are valued. Such acknowledgment can substantially boost morale, encouraging staff to take pride in their job. Consequently, workers are more most likely to collaborate properly, share concepts, and involve completely in their duties. Inevitably, a well-maintained workplace not only enhances performance however also grows a society of teamwork and inspiration, leading to enhanced overall efficiency within the organization.

Making Certain Conformity With Safety Standards

Compliance with safety and security criteria may appear like a tough task, it is necessary for maintaining a risk-free and efficient office. Regular upkeep and prompt repair services of strapping devices play a crucial duty in adhering to these criteria. When equipments are not working appropriately, they can posture significant safety risks to workers, leading to mishaps and potentially severe injuries.

By ensuring that strapping devices remain in excellent working problem, companies can reduce dangers and promote a culture of security. Normal assessments and prompt fixings not just aid in conference regulative requirements however likewise enhance operational performance. Furthermore, conformity with safety and security criteria can result in minimized liability and insurance prices, benefiting the organization economically.

Ultimately, purchasing prompt repair solutions for strapping equipments is a positive method that sustains both staff member well-being and operational honesty, underscoring the relevance of safety and security in the workplace.

Developing a Trustworthy Supply Chain With Reliable Repairs

Efficient fixings of strapping equipments are crucial for developing a reputable supply chain. When strapping machines run at peak performance, they aid preserve the flow of goods, minimizing hold-ups and making certain prompt delivery of items. Break downs can disrupt procedures, leading to production bottlenecks and enhanced costs, which ultimately affect consumer contentment.

Regular upkeep and timely repair work minimize the danger of unanticipated failures, permitting businesses to plan their operations successfully. By purchasing prompt repair work solutions, business can boost the longevity of their tools, ensuring consistent efficiency.

A well-maintained strapping device decreases the chance of defective packaging, securing product integrity throughout transportation. This integrity fosters count on in between customers and distributors, enhancing lasting partnerships. In turn, a solid supply chain improved efficient repair work not just enhances functional performance but additionally adds to overall business growth and profitability.

Regularly Asked Concerns

Just How Usually Should Strapping Machines Be Serviced?

Strapping makers must preferably be serviced every six months to ensure peak performance. Routine upkeep checks can stop unanticipated malfunctions, enhance efficiency, and extend the life-span of the equipment, eventually supporting constant operational effectiveness.

What Prevail Indications of Strapping Machine Issues?

Can I Carry Out Basic Maintenance Myself?

Exist Guarantees on Repair Services?

Warranties on fixing services differ by service provider. Some business offer restricted guarantees covering components and labor for a specific period, while others may not more info give any. It's a good idea to ask about guarantee information before service initiation.

Exactly how Do I Select a Trusted Repair Service?

To choose a reliable repair work service, one ought to look into consumer reviews, verify credentials, assess experience, demand quotes, and make inquiries about warranties. This strategy guarantees informed decisions and enhances the possibility of getting high quality solution.

By focusing on timely strapping device fixings, organizations can maintain constant throughput, boost efficiency, and eventually guard their lower line. Routine upkeep plays a substantial function in enhancing the life expectancy of strapping makers, complementing the benefits of prompt repair services. Timely fixings and maintenance of strapping machines assist keep this essential consistency, protecting against fluctuations that can impact overall item top quality. Preventative repair work in strapping makers can lead to significant price financial savings for companies. Regular maintenance and timely repairs of strapping makers play an important function in sticking to these standards.